PLBK-14.0-5000

Multi-functional Knee-type Automatic Machine for Stone Processing

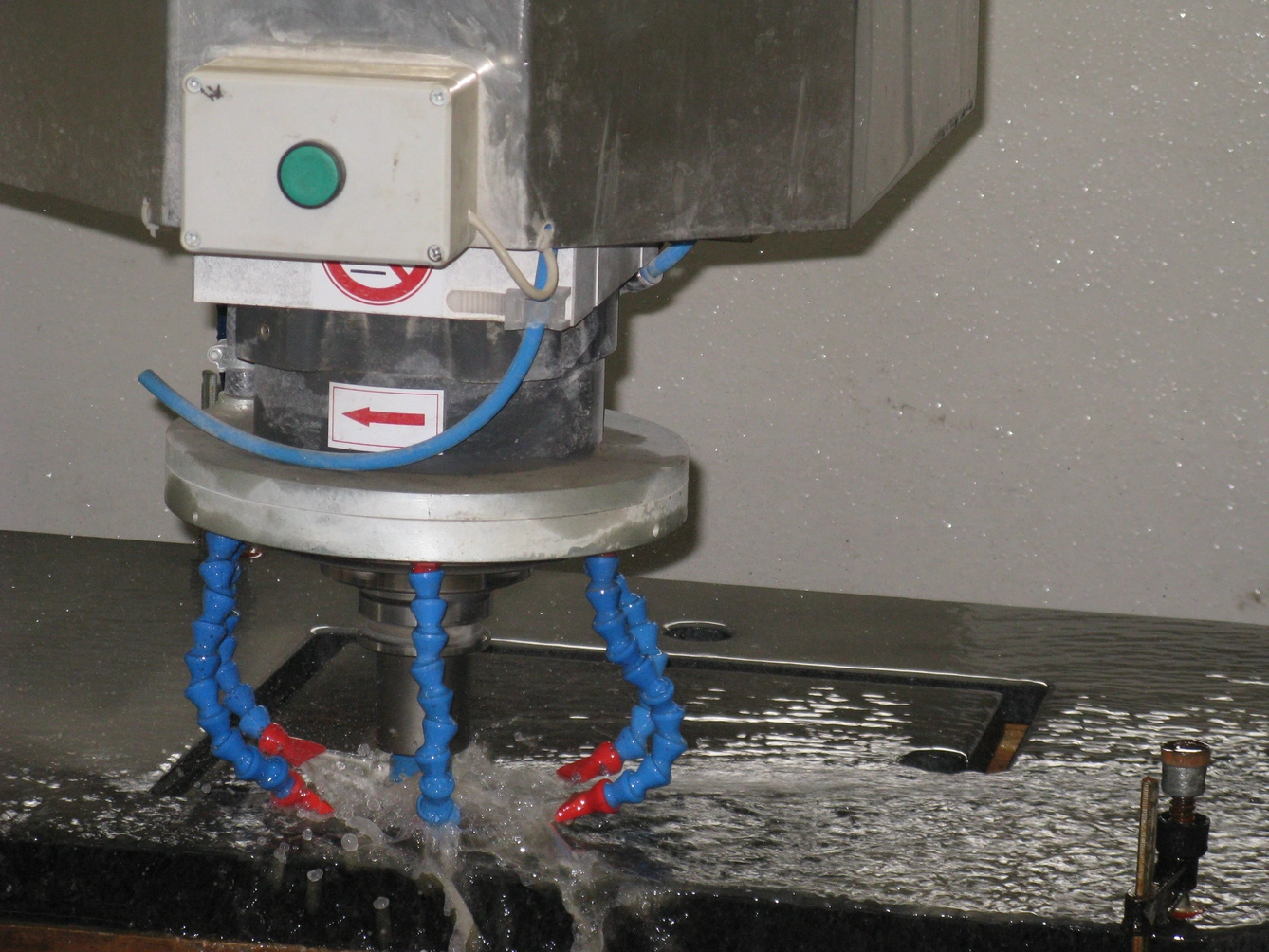

PROMASZ WMKK-14.0-02-AUTOMATIC is a multifunctional knee machine designed for precise tasks such as milling, grinding, drilling, hole cutting and edge machining (e.g. for sinks or kitchen countertops). It is distinguished by automation thanks to servo drives that have replaced manual head guidance, guaranteeing repeatability and precision. A graphic control panel makes it easy to design and visualize machining. With a work area of 1000x2000 mm, the machine allows you to create, edit and save contours and holes, as well as build your own pattern library. Data can also be stored externally.

Technical Data

- Working Area: 1000×2000 mm

- Cutting Speed: from 0 to 500 mm/min

- Fast Traverse Speed: 2 mm/min

- Slab Thickness: up to 500 mm (possible to increase this dimension upon agreement with the manufacturer)

- Wire Speed Control: Stepless regulation

- Servo Drives: In two axes

- Wire Construction: Wrapped around three wheels

- Drive: Gearbox between the drive wheel and the drive for significantly increased starting torque

Installation Requirements

- Power supply cable: 5×6 mm2 copper

- Network protection before the machine: C32-3P

- Grounding: Before start-up, all fixed metal parts should be connected with a grounding strip of min 120 mm2 to the PE of the electrical installation.

- Utilities: Electricity, water, and compressed air should be supplied to the foundations from the control cabinet side.

Have questions? We have answers

Important details about machine operation and configuration

Got questions about our offer and working with us? The answer could be here.

Maszyna jest wielofunkcyjnym urządzeniem do frezowania, szlifowania, wiercenia, wycinania otworów oraz obróbki boczków wewnętrznych i zewnętrznych płyt kamiennych.

Ręczne prowadzenie głowicy zostało zastąpione serwonapędami dla precyzyjnej pracy automatycznej, a wzornik zastąpiono graficznym panelem sterowania do bezpośredniego projektowania.

Tak, maszyna umożliwia tworzenie, zapis i edycję konturów lub otworów bezpośrednio za pomocą panelu graficznego, a także tworzenie własnej biblioteki.

Maszyna jest przeznaczona do obróbki płyt o grubości do 500 mm, z możliwością zwiększenia tego wymiaru po uzgodnieniu z producentem.

Wymagane są zabezpieczenia w sieci przed maszyną typu C32-3P.

Trust the experts in your industry

Do you have any questions? Get in touch with us!

Are you looking for a specific machine, want to consult on a project or need a customized quote? Our technical advisors will be happy to help you select a solution tailored to your production.

Fill out the form and we will contact you within 48 hours. We offer:

- Technical consultation

- Individual pricing

- Individual pricing

Trust the experience of PROMASZ – choose proven technologies for your plant.

Latest News

Stay up to date

Follow the latest news from our company, discover our new products, get insights from industry events, and stay up-to-date with our achievements.