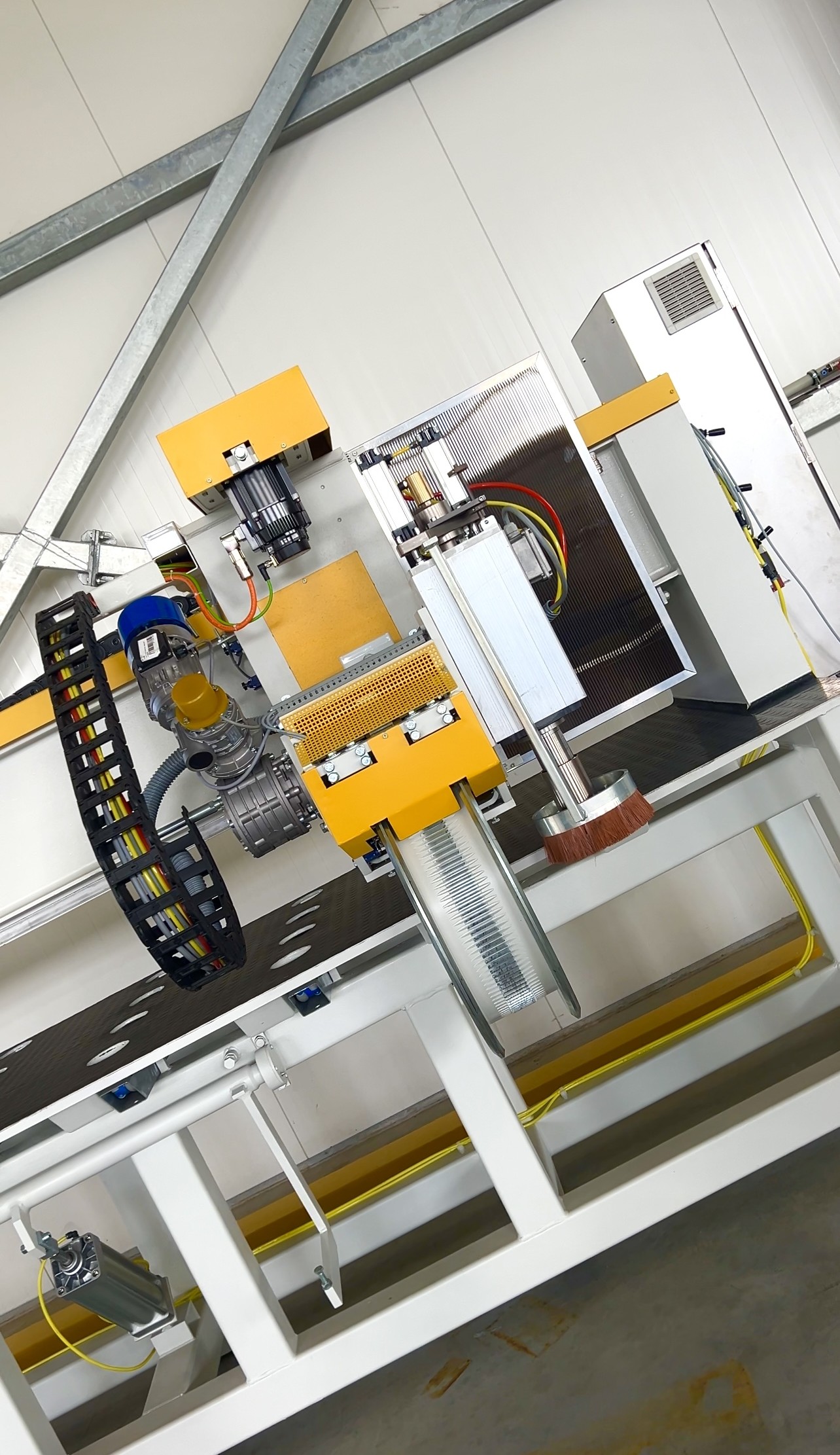

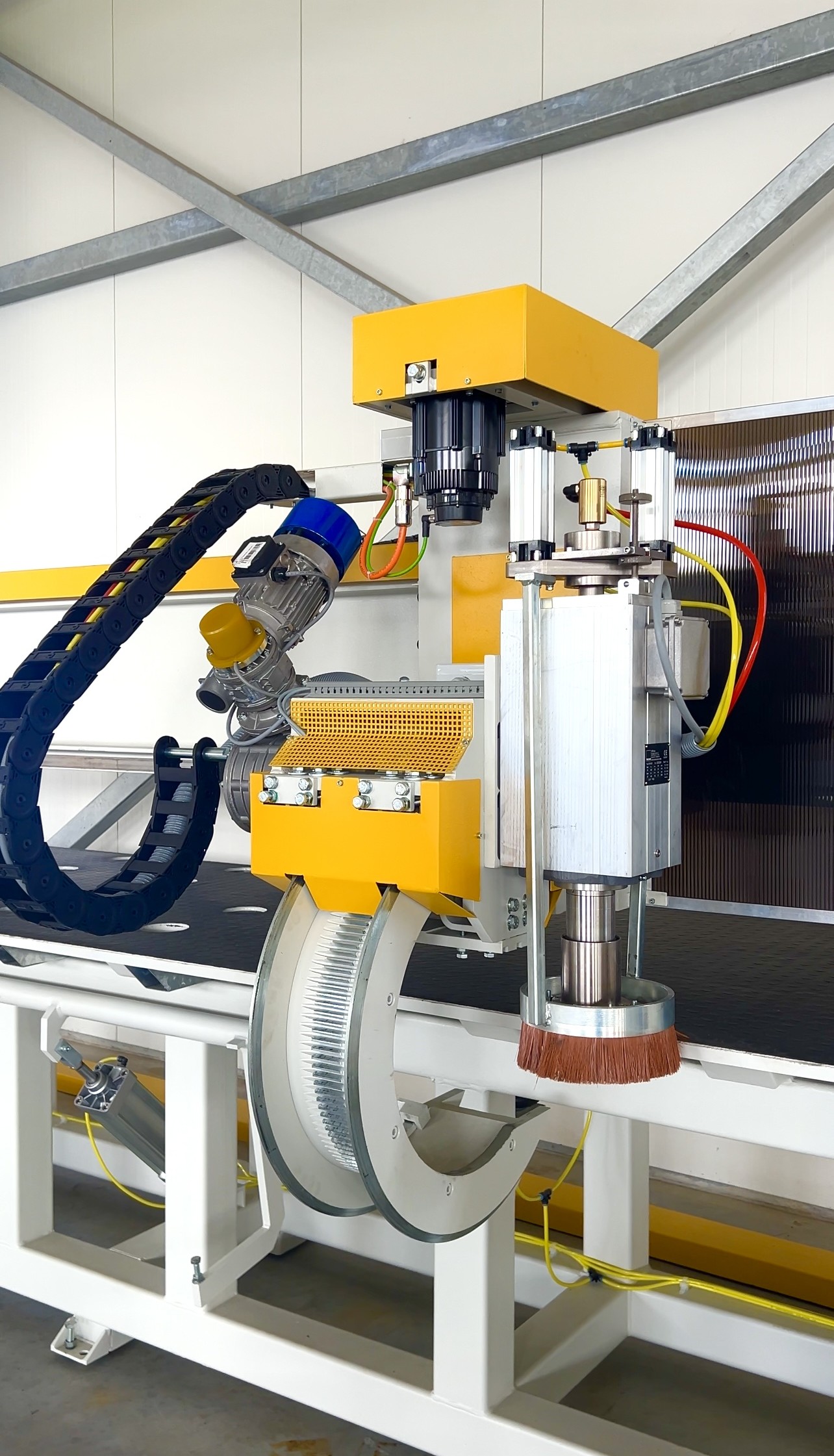

B1PK-14.0-2000.2S

Profile Edge Polishing Machine

A professional profiling edge polisher designed for precise processing of natural stone (marble, granite, conglomerate). Equipped with servo drives, the machine significantly reduces processing time, enables circular movement, and ensures extremely accurate setup movements. It features an advanced control system with a touchscreen operator panel.

Technical Specifications

- Max material processing length: 3 meters

- Max slab thickness: 100 mm

- Upper movement: linear bearings in an oil bath

- Vertical movement (up/down): ball screw + linear bearings

- Slab feed and rotation: set of multi-directional pneumatically lifted rollers

- Pneumatic clamps: 3 actuators

- Smooth speed control with soft start/stop: servo drives

- Water pressure sensor included

- Structure coated with structural lacquer

- Control: PLC + touchscreen panel

Installation Requirements

- Power supply: 3 x 400 V + N + PE

- Power cable: 5 x 6 mm² (copper)

- Protection: D40 – 3P

- Grounding: minimum 120 mm² grounding strip to PE

- Utilities: electricity, water, compressed air supplied at the foundation from the control cabinet side

Key features included as standard

Standard equipment and systems you receive immediately

The standard machine includes everything you need to start working right away – from the main frame and spindle to the control system. All parts are industrially tested and ensure high precision and reliable performance day after day.

Standard Equipment

- Stainless steel control cabinet

- Multi-directional pneumatic rollers

- Touchscreen operator panel

- Auxiliary handheld remote control for positioning

- Pressure sensors, solenoid valves, proportional valves

Core System

- Servo drives enabling smooth acceleration and deceleration

- Fully programmable operation via PLC

- Memory function for different operation parameters through the touchscreen panel

Working modes

- Setting movement (handheld remote control)

- Programmable circular and linear motion

- Durable structural lacquer finish

- Compact dimensions:

- Height: 2270 mm

- Width: 2500 mm

- Length: 4900 mm

The machine scales with your production

Extend functionality, amplify potential

You can equip any model with extra functionalities designed for your exact requirements – including expanded CNC control, material lifting and transport solutions, and CAD/CAM/3D modules. Thanks to its modular design, you can easily expand the machine at any time during its lifespan.

Optional Equipment

- Custom dimensions

- Extended roller table

- Rotation table (turntable)

- Additional clamping devices

- Extra clamping actuator

- Additional valves for pneumatic actuators

Attention: The modification options and optional equipment shown are available for an additional charge. This description is provided for information only.

Extended System / Control Options

- 10” touchscreen panel

- Central lubrication system

Attention: The modification options and optional equipment shown are available for an additional charge. This description is provided for information only.

Other Options

- Safety enclosure for the working area: Installed by PROMASZ (based on client-provided documentation) alternatively, client-supplied and installed

Attention: The modification options and optional equipment shown are available for an additional charge. This description is provided for information only.

Have questions? We have answers

Important details about machine operation and configuration

Got questions about our offer and working with us? The answer could be here.

Yes, with a PLC and touch panel, the operator can program the operating parameters.

Yes, non-standard designs are possible on request.

Yes, the machine makes it possible to realize circular motion thanks to servo drives.

Electricity, water, compressed air, proper protection and grounding of the foundation.

Yes, PROMASZ can make the fence after providing documentation from the customer.

Trust the experts in your industry

Do you have any questions? Get in touch with us!

Are you looking for a specific machine, want to consult on a project or need a customized quote? Our technical advisors will be happy to help you select a solution tailored to your production.

Fill out the form and we will contact you within 48 hours. We offer:

- Technical consultation

- Individual pricing

- Individual pricing

Trust the experience of PROMASZ – choose proven technologies for your plant.

Latest News

Stay up to date

Follow the latest news from our company, discover our new products, get insights from industry events, and stay up-to-date with our achievements.