AS-14.0-01.1

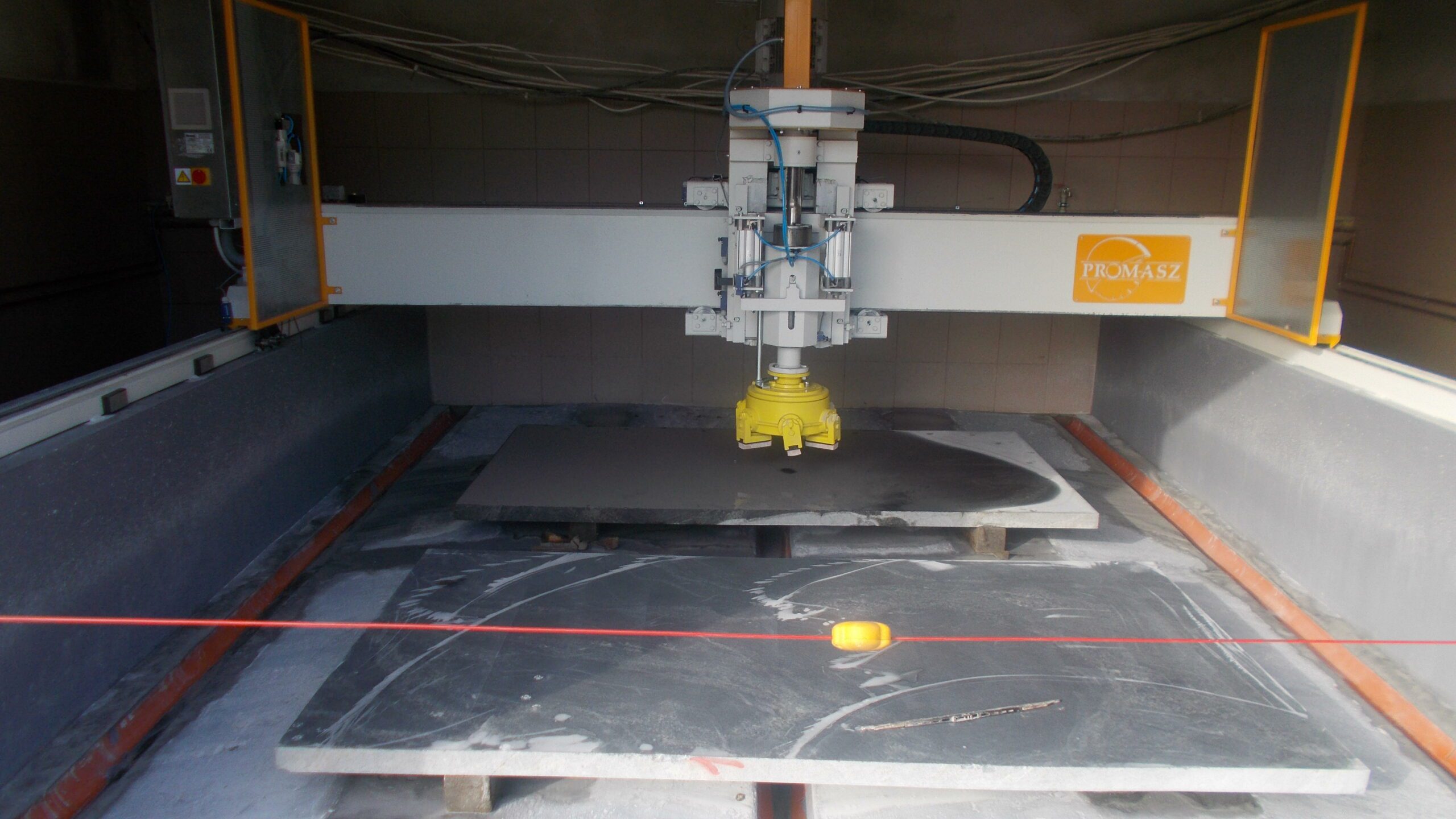

Stone Polishing Machine

An industrial machine designed for grinding and polishing stone slabs (granite, marble, etc.) up to 30 cm thick with a working area of 3200 x 3200 mm.

Built with a rigid steel frame, the AS-14.0-01.1 ensures durability and high performance. Equipped with automated control, it enables the processing of multiple slabs in continuous operation.

Technical Specifications

- Max material thickness: 30 cm

- Working area: 3200 x 3200 mm

- Main motor: 11 kW

- Spindle speed: 420 RPM

- Feed speed (X/Y): 0.5 – 4 m/min (via inverters)

- Machine dimensions: 4500 x 4500 x 2200 mm

- Head pressure: Pneumatic (0.05–0.1 MPa)

Installation Requirements

- Power supply: 3x400 V + N + PE, 13 kVA

- Power cable: 5 x 6 mm²

- Circuit protection: D40 – 3P

- Grounding: grounding strip min. 120 mm²

- Utilities: electricity, water, compressed air routed to machine foundation (near control cabinet)

Key features included as standard

Standard equipment and systems you receive immediately

The standard machine includes everything you need to start working right away – from the main frame and spindle to the control system. All parts are industrially tested and ensure high precision and reliable performance day after day.

Standard Equipment

- Steel frame with precision guides

- Cross-slide spindle carriage

- Pneumatic + mechanical head height adjustment

- Control cabinet on the right-hand side

Core System

- Programmable controller with touchscreen interface

- Manual mode (setup) and automatic mode (programmed sequences)

- Positioning system with proximity sensors and magnetic plates

Motion Types

- Longitudinal and cross movement with adjustable stroke

- Zigzag movement (wave pattern): 0–300 mm

- Circular movement (along the slab edge)

- Custom motion combinations and programmable polishing cycles supported

Additional Base Information

- Multiple slab processing with automated head transition

- Head auto-lift for slab switching

- Dual-system head height regulation for flexibility and stability

The machine scales with your production

Extend functionality, amplify potential

You can equip any model with extra functionalities designed for your exact requirements – including expanded CNC control, material lifting and transport solutions, and CAD/CAM/3D modules. Thanks to its modular design, you can easily expand the machine at any time during its lifespan.

Optional Equipment

- Extended tracks

- Reinforced H-beam tracks (with threaded adjustment)

- Remote control for X and Y axes

- Water solenoid valve

Attention: The modification options and optional equipment shown are available for an additional charge. This description is provided for information only.

Extended System / Control Options

- Soft-start system for main motor

- Inverter for main motor control

Attention: The modification options and optional equipment shown are available for an additional charge. This description is provided for information only.

Other Options

- Custom bridge dimensions available

- Protective workstation fencing available:

- Installed by PROMASZ (upon client's layout delivery) or built by the client per their own design and materials

Attention: The modification options and optional equipment shown are available for an additional charge. This description is provided for information only.

Have questions? We have answers

Important details about machine operation and configuration

Got questions about our offer and working with us? The answer could be here.

Yes, it has a programmable controller and a touch panel with the ability to create machining cycles.

Yes, the option of making a bridge or track in a non-standard size is available.

The machine automatically moves from one plate to the next by controlling the head lift.

Utilities (electricity, water, air), proper grounding and power cable should be brought to the foundations.

Yes, the customer can prepare them on his own or choose to have the fence made by our company.

Trust the experts in your industry

Do you have any questions? Get in touch with us!

Are you looking for a specific machine, want to consult on a project or need a customized quote? Our technical advisors will be happy to help you select a solution tailored to your production.

Fill out the form and we will contact you within 48 hours. We offer:

- Technical consultation

- Individual pricing

- Individual pricing

Trust the experience of PROMASZ – choose proven technologies for your plant.

Latest News

Stay up to date

Follow the latest news from our company, discover our new products, get insights from industry events, and stay up-to-date with our achievements.