AS-14.0-03 (serwo Mitsubishi)

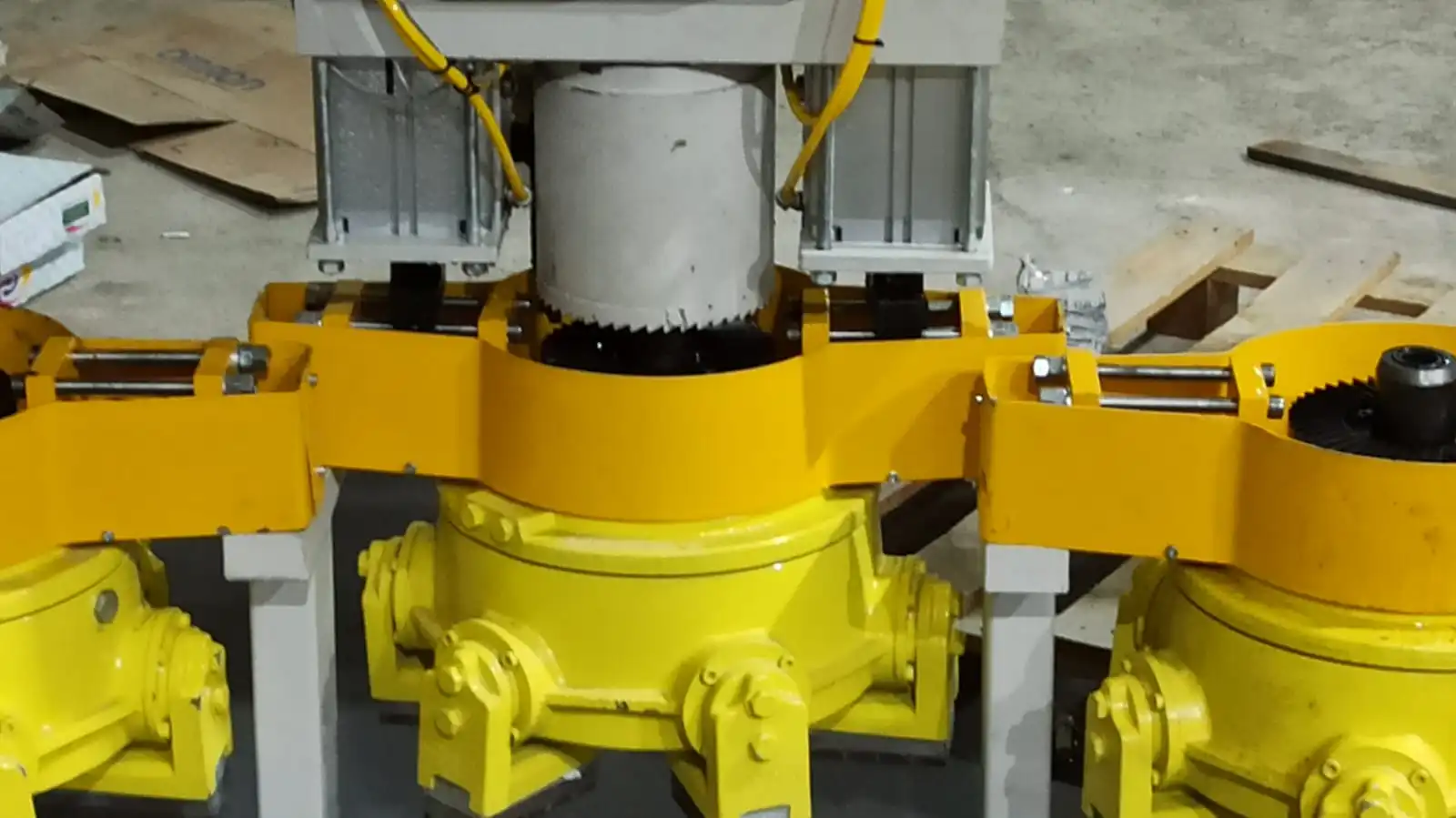

Stone Polishing Machine

A professional-grade machine designed for grinding and polishing natural stone slabs (granite, marble) with a maximum thickness of up to 30 cm.

Featuring a robust steel frame, precise linear guides, and Mitsubishi automation, the AS-14.0-03 ensures durability, reliability, and efficiency for continuous industrial use.

Technical Specifications

- Max material thickness: 30 cm

- Frame: Steel with linear guides in oil baths

- Cross movement: spindle on a movable carriage

- Longitudinal movement: entire unit on oil-bathed rails over concrete walls

- Head height adjustment: mechanical (screw system) + pneumatic (2 cylinders)

- Additionally: possibility to add a warehouse with automatic tool exchange

Installation Requirements

- Power supply: cable 5x6 mm², protection D40 – 3P

- Grounding: minimum 120 mm² grounding strip to PE

- Media: power, water, compressed air — routed to the control cabinet side

Key features included as standard

Standard equipment and systems you receive immediately

The standard machine includes everything you need to start working right away – from the main frame and spindle to the control system. All parts are industrially tested and ensure high precision and reliable performance day after day.

Basic Equipment

- Spindle and movable carriage

- Longitudinal and cross movement support

- Adjustable head height (mechanical + pneumatic

- Touchscreen control panel

Core System

- Control system: Mitsubishi (PLC + HMI)

- Modes: manual (positioning) and automatic (programmed sequences)

- Programmable motion cycles

- Highly accurate head motion and repeatability

Working motion types

- Longitudinal movement

- Cross movement

- Zigzag (wave motion, adjustable 0–300 mm)

- Circular movement (along the contour)

- Rotational movement

- Can combine motion types and assign custom polishing cycles

Other Key Features

- Supports batch processing of multiple slabs with automatic head positioning

The machine scales with your production

Extend functionality, amplify potential

You can equip any model with extra functionalities designed for your exact requirements – including expanded CNC control, material lifting and transport solutions, and CAD/CAM/3D modules. Thanks to its modular design, you can easily expand the machine at any time during its lifespan.

Advanced System / Control Options

- COMES or GAM polishing head

- Extended guide rails

- Hydraulic table: 3400 x 1900 mm

- Inspection camera

Attention: The modification options and optional equipment shown are available for an additional charge. This description is provided for information only.

Dodatkowy system / sterowanie

- Centralized automatic lubrication

- Steel foundation option (instead of concrete)

Attention: The modification options and optional equipment shown are available for an additional charge. This description is provided for information only.

Other Customizations

- Custom machine sizes available

- Full configuration based on client specifications

Attention: The modification options and optional equipment shown are available for an additional charge. This description is provided for information only.

Have questions? We have answers

Important details about machine operation and configuration

Got questions about our offer and working with us? The answer could be here.

Yes, thanks to a movable slide and different types of working movements, the device handles plates of different shapes and sizes.

The machine can be equipped with different heads, a hydraulic table, a camera or longer tracks - it all depends on production needs.

Yes, the machine has a touch panel with an intuitive interface and the ability to program multiple machining cycles.

Yes, the machine automatically moves to the next plate with head elevation control.

Lead time depends on the machine version and individual arrangements.

Trust the experts in your industry

Do you have any questions? Get in touch with us!

Are you looking for a specific machine, want to consult on a project or need a customized quote? Our technical advisors will be happy to help you select a solution tailored to your production.

Fill out the form and we will contact you within 48 hours. We offer:

- Technical consultation

- Individual pricing

- Individual pricing

Trust the experience of PROMASZ – choose proven technologies for your plant.

Latest News

Stay up to date

Follow the latest news from our company, discover our new products, get insights from industry events, and stay up-to-date with our achievements.